What is the Haldex clutch and rear differential service interval?

The service intervals of Haldex clutches and rear axle differentials have changed from time to time with the development of newer generations. In any case, there is no "lifetime" oil filling. Oil fillings in gearboxes, differentials and transmissions from the manufacturer are often referred as "lifetime", because their service interval exceeds the standard length of the new car's warranty period (frequently 4 years) and after this period the manufacturer no longer guarantees any warranty on these mechanisms.

Standard length of the service interval of oil and filter in Haldex clutch is set to every 60,000 kilometres. We recommend to keep this service intervals. If the vehicle is not frequently driven of longer routes, so we recommend to keep the time service interval of 3 years, because of degradation of the oil filling by air humidity, which leak to the haldex system.

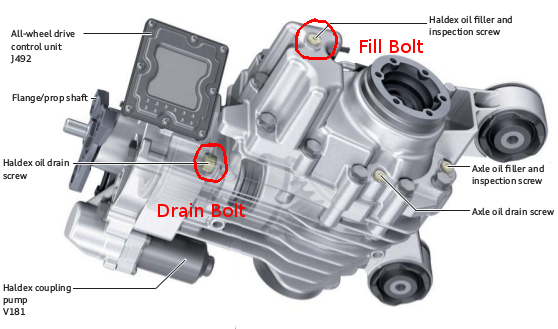

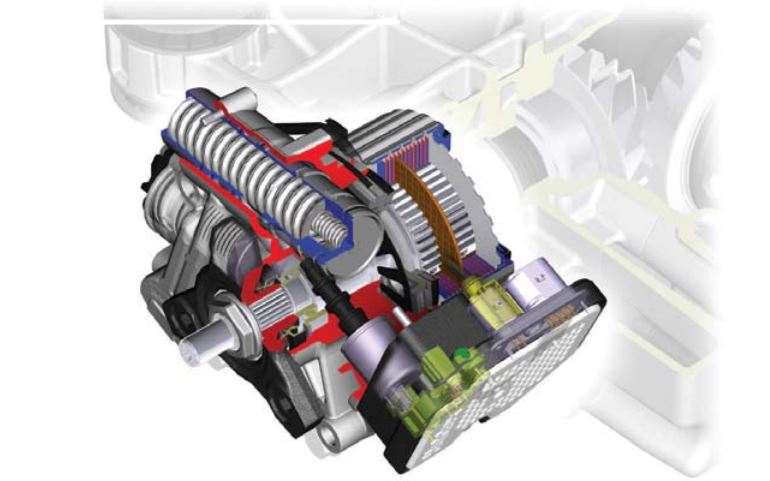

In the practise, the Haldex clutch is connected with rear differential in a one common block. Here is necessary to know, that the oil filling of haldex clutch is separated from oil filling of rear differential. Their oil fillings have different requirements. Haldex clutch needs the hydraulic oil certified for hydraulic systems and differential needs the lubricating oil for its mechanism. The drain and fill bolt of the haldex clutch si marked on the picture below. There is a 5th generation of haldex on the picture.

Towing a vehicle with the Haldex clutch is allowed on the maximal distance of 50 kilometres and by maximal velocity 50km/h only, because there is the menace of the haldex clutch failure by mechanical seizure.

Principle of operation and check of the correct function of Haldex:

1st generation

The first-generation of Haldex clutch has been developed for greater vehicle stability and safety, as well as an alternative to the previously used direct all-wheel drive, that Audi has launched with its Quattro model. The Haldex clutch should provide all-wheel drive only in situations where the vehicle was skidding, accelerating or driving on an unpaved surface, so it should serve for the purpose of all-wheel drive only, when the situation required it, thus save the fuel and weight compared to vehicles with non-detachable all-wheel drive. The first generation of haldex works on a simple principle, when the ABS sensor on the right front wheel detect the slip, then ESP sends a signal based on the steering wheel angle sensor to the Haldex control unit, which increases the oil pressure through the hydraulic pump, oil presses on the clutch plates and put Haldex into operation. Haldex of the 1st and 2nd generation are systems working on the so-called post eventual or reactive principle, i.e. it is activated after the vehicle gets into a problematic situation only. However, it does not take longer than 1/4 turn of the wheel to the fully active all-wheel drive.

Service set of pump + filter + oil is available here.

2nd generation

This generation still uses a mechanical hydraulic pump, but the linear throttle (pressure) valve has been replaced by a solenoid, that controls the operation of the proportional pressure valve. As well as the first generation, it works on the reactive principle. The electronics are only able to reduce the oil pressure when parking, working with ABS, applying the parking brake, etc., but cannot preload the clutch. The service set of pump + filter + oil is available here.

The correct function of the first and second generation can be detect:

1. We lift the car onto the jack so, that the wheels do not touch the ground, then we start the engine, shift the 1st gear or in the case of the automatic transmission we put it in "D" and watch whether all 4 wheels turn. Then apply the parking brake and see if the rear wheels have stopped turning. If so, the Haldex clutch function is correct. However, if the rear wheels still rotate, the Haldex clutch is engaged and possible causes of the fault must be sought: blocked main pressure valve (pump), control unit - J492 Haldex clutch is defective, parking brake lamp switch may be defective, mechanical fault on Haldex clutch.

2. Lift the car onto the jack so, that the wheels do not touch the ground, continue to start of engine, engage 2nd gear or "D", apply the parking brake and let the clutch slowly engage, the engine must stop. If the engine has stopped, the Haldex clutch is engaged and its function is correct. However, if the engine has not stopped, the Haldex clutch is not engaged and it is necessary to look for possible causes of the fault: blocked main pressure valve or pump, Haldex control unit - J492 is defective, mechanical fault..

The possible cause of the noise can be detected at first by disconnecting the connector on the haldex clutch pump or the ABS fuse. If the noise ceases, it is not a mechanical fault, but an electrical one, where the pump is defective in 95% of cases, ABS sensor on the front right wheel is defective in 2% of cases, Control Unit of haldex clutch is defective in 2% or steering angle sensor in 1%. If the noise or locking of the vehicle occurs when turning the steering wheel only, it can be detected by disconnecting the steering wheel angle sensor. If the noise or locking of the wheels disappears, check the steering wheel angle sensor, wiring of Control Unit, etc.

3rd generation

Haldex couplings of this generation were already able to pre-tension the coupling with pump. From this generation, Haldex systems have become proactive, thus the electronics can activate all-wheel drive before the wheel slips.

This generation was montaged to vehicles of the brand Volvo (OE number 30783079), Land Rover (OE number LR003147) and Ford (OE number 8V414C019AA) only. The VW Group did not montaged this generation in its vehicles.

4th generation

In 2008, the 4th generation Haldex clutch was released and it no more used a mechanical hydraulic pump. The clutch is activated via the feed pump. The technical documentation many times indicates, that the oil filter in haldex clutch at this generation is "lifetime", but we recommend to change the filter with the oil for the carefree longevity of the Haldex clutch. We also offer the filter in our e-shop under OE number 2003085 for VW's vehicles and 2002968 for others vehicles (Volvo, Land Rover, Ford). For Opel's and Saab's vehicles exist the set of filter with seal (OE number 20986573), because their Haldex coupling is structurally different.

The system works as follows:

- Engine speed sensor (G28) and position sensor of accelerator pedal (G79) communicate with Engine Control Unit (J623)

- The wheel speed sensor (G44-G47) and the brake light switch communicate with the Control Unit of ABS / ESP (J104)

- Engine Control Unit + ABS/ESP Control Unit + steering wheel angle sensor (G58) + GATEWAY data bus diagnostic interface (J533) communicate with Control Unit of Haldex clutch (J492)

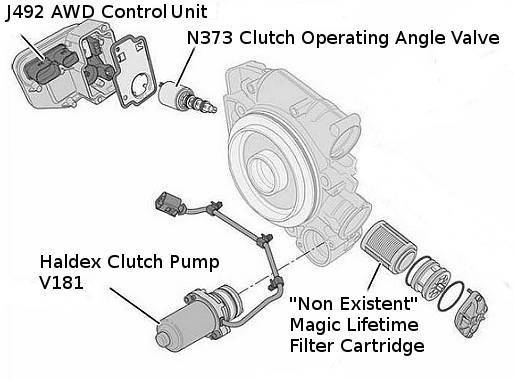

- Control Unit of Haldex clutch gives instructions via the CAN bus to the Haldex pump (V181) and to the solenoid valve for regulating of the clutch opening degree (N373), which regulates the oil pressure. It controls the all-wheel drive based on the signal from the control module of Haldex. The magnitude of the pressure depends on the magnitude of the electrical current and there is assigned a precisely defined value of the pressure generated by the control solenoid valve. It must also work depending on the acceleration, deceleration, driving speed, stopping and parking of the vehicle.

- Haldex pump with oil pressure accumulator create a pressure of 3 MPa. By supplying the coil of the electromagnet, an electromagnetic field is created, where its magnitude depends on the value of the electrical current. The resulting field generates a force, that sets the control piston in motion. Control piston opens the flow of the pressurized oil to the working piston.

- Furthermore, this system regulates driving on slippery roads, acceleration with a slip of the wheels and in the event of ABS / ESP intervention.

- If the Control Unit of Haldex clutch has malfunction, the clutch is disengaged and the transmission of driving torque to the rear axle is not working.

Inspection of 4th generation Haldex clutch with car on jack:

1. Start the engine, shift 1st gear or "D" and slowly release the clutch / brake pedal. All 4 wheels must rotate.

2. Apply the parking brake, the rear wheels must stop and the front wheels continue to rotate.

3. Release the parking brake, still shifted 1st gear or "D", depress the accelerator pedal to 20% - 30% level and slowly apply the parking brake, the rear wheels must try to turn.

4. If the Haldex test is performed according to the described procedure, the function of the Hadex clutch is correct.

5th generation

This generation came on the market in 2012 and was structurally simpler and 1.5 kg lighter than the 4th generation. Compared to the 4th generation Haldex clutch, the oil pressure reservoir, solenoid valve and filter are eliminated. The oil pressure on the clutch plates is regulated by a centrifugal valve integrated in an electrically driven six-piston oil pump. By this it responds to changes in driving conditions within a few milliseconds. The Control Unit works with a logarithm that recognizes the wheel diameters, the air pressure and thus adjusts the clutch operation. It is also ready for possible tire damage and a drive with an emergency wheel. The 5th generation of Haldex has proved its worth and is therefore still installed in vehicles.

This generation does not use a filter, so it needs to only change oil at an interval of 60,000km or 3 years.

Often when haldex of 5th generation does not drive, there can be typically no warning lights or error messages shown on the dashboard to illustrate the system is faulty, thus owners are unaware of the issue. Haldex clutch of second hand cars often does not work, so then owners never know any different. Only when it comes to winter time where they get stuck somewhere they then realize the rear wheels are not turning. Cars such as Golf R, RS3, S3, TTS or TTRS with more performance, the lack of 4wd is more apparent as brisk acceleration usually causes the traction light to flash and power be limited – accompanied by lots of wheel spin, especially on wet roads or slippy surfaces.

When scanning the vehicle for fault codes, it is important to use some decent scanning system which can actually communicate with the Haldex control module which is “22 AWD”. Fault codes which often occur are:

- 131599 – All Wheel Drive Clutch – U0114 00 [009] – No Communication (ECU fault)

- 131599 – Control Module for All Wheel Drive Clutch – C1113 07 Intermittent error (ECU fault)

- 16670 – All-Wheel Drive – C1113 07 [008] – Mechanical Failure (Pump fault OR/AND transfer box)

- 16671 – Pump for Haldex Clutch – C1112 04 [008] Internal System Fault (Faulty pump AND ECU repair)

- 16671 – Haldex clutch pump Faulty – C1112 04 passive/sporadic (Faulty pump AND ECU repair)

- 16668 – Pump for Haldex Clutch C1112 07 [008] – Mechanical Failure Intermittent (Pump fault)

- 16666 – Pump for Haldex Clutch C1112 13 [008] – Open Circuit (Pump fault)

- C111307 – Mechanincal Malfunction – Passive / Sporadic (Blocked pump, clean out and relearn OR transfer box)

The source of information was the sites prevodovky-sixta.cz, https://www.awdwiki.com/en/haldex/ and own experience and knowledge of the eshop provider.